Porcelain Insulator News

by Elton Gish, NIA #41

Reprinted from "INSULATORS - Crown Jewels of the Wire", August 1984, page 24

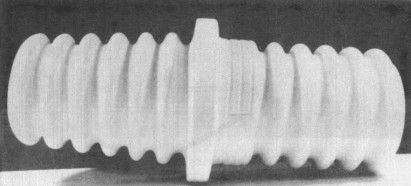

The Imperial bushing pictured

below was first reported in this column April, 1981 on page 22. It is 12"

long and is incuse marked on the wide center ring: IMPERIAL 116597

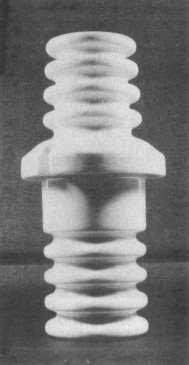

There is a

second Imperial bushing known (pictured 2nd) that is much smaller. It is

5-5/8" long and has an incuse marking below the wide central ring:

IMPERIAL

38922

Little is known about Imperial history. We only know about their pin types

because of the many styles that exist with Imperial markings. Specimen evidence

indicates that Imperial got out of the pin types about 1904, as the latest known

date is 3-17-04. This date was found on a brown sim U-710. They could have

likewise stopped production at that time of other HV types such as these

bushings. The company continued to make porcelain items, including wiring

insulators for many years until about the time of the depression. We never have

been able to get any direct info (catalogs, etc.) on Imperial, only material

indirectly from other sources, other jobber catalogs, etc. The door is wide open

to anyone with the time to go to Trenton, New Jersey, to research old city

directories, etc., to learn more about this early company.

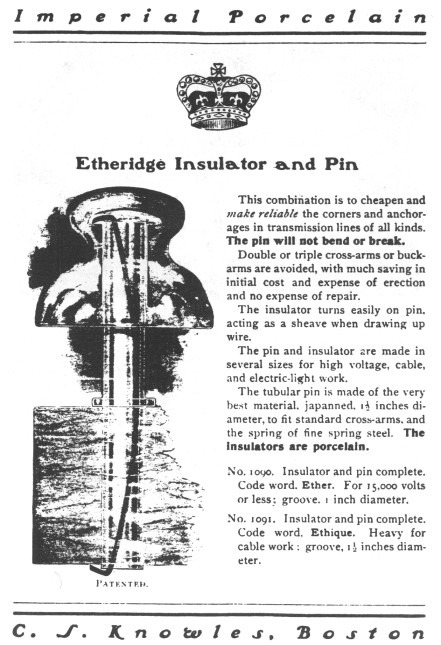

Several years ago,

Ray Klingensmith sent me this copy of a page from a C. S. Knowles catalog.

Knowles was a jobber of Imperial pin types. The illustration is of a U-376A

Etheridge insulator and pin assembly made by Imperial Porcelain.

Large Image (239 Kb) |

(text from image)

Imperial

Porcelain

Etheridge Insulator and Pin

This combination is to cheapen and make

reliable the corners and anchorages in transmission lines of all kinds. The pin

will not bond or break.

Double or triple cross-arms or buck-arms are avoided,

with much saving in initial cost and expense of erection and no expense of

repair.

The insulator turns easily on pin. Acting as a sheave when drawing up

wire.

The pin and insulator are made in several sizes for high voltage, cable,

and electric-light work.

The tubular pin is made of the very best material.

japanned. 1-1/2" inches diameter, to fit standard cross-arms. and the

spring of fine spring steel. The Insulators are porcelain.

No. 1090. Insulator

and pin complete. Code word. Ether. For 15,000 volts or less.; groove. 1 inch

diameter.

No. 1091. Insulator and pin complete. Code word, Ethique. Heavy for

cable work: groove, 1-1/2" inches diameter.

|

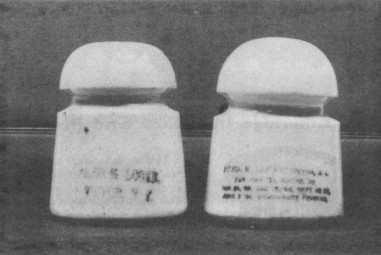

The next photo is of two U-3's

with Fred Locke markings 0-5 AN6 6-3. These are underglaze markings in green

ink. Underglaze markings on Fred Locke Pony insulators are very rare, if not

unique. These were first cataloged by Locke in 1899 as the No. 6 Pony. The No. 6

Pony was changed to U-38 in 1902. Locke catalogs have not been found for

1903-1906, but Ohio-Brass was a selling agent of "Victor" insulators

and listed the U-3 in their 1905 catalog as the "Victor" Pony No. 9.

It was listed as such in Locke catalogs for many years after that.

The photo is

also a good example of the many variations found in Fred Locke insulators of the

same U-#. The position, shape and depth of the wire groove added by green

trimming is not a constant. The overall insulator body is pressed in a hollow

cavity (no groove) and, after the damp insulator has been "cured" a

day, it is mounted on a spindle operated by a foot-switch and spun, the side

groove being trimmed in with a cutter swung over against the spinning insulator.

For something as simple as the U-3, the whole trimming cycle for the operator

would be less than five seconds -- about ten or more trimmed per minute. Groove

height would depend on how the insulator seated on the spindle, how the trimmer

was set up, how sloppy the arm was hinged, etc. Depth is controlled only by

operator eye in that split second it takes to do it. Groove shape is just how

the trimmer blade was shaped. They look like pieces of scrap "tin",

but are probably made of something better that will take a temper as old hacksaw

blades or any type of spring steel strip. Thus, unless obviously meant to be

different in a gross way, we can't consider these variations as different

"styles" and assign them different U-#'s.

|